The biological filter, or biofilter, is a key component in the filtration portion of a recirculating aquaculture system (RAS). The biofilter houses the nitrifying bacteria and is the primary site where biological nitrification occurs. Nitrifying bacteria process dissolved nitrogenous waste products excreted by the aquatic organisms being cultured. All cultured organisms, vertebrates or invertebrates, finfish or shellfish, produce waste as a result of the nutrition they receive. Finfish excrete ammonia (NH3), mostly from their gills, and it dissolves in the water in which the fish must live.

This waste product is toxic to the fish and is an environmental stressor that causes reduced appetite, reduced growth rate, and death at high concentrations.

Fortunately, naturally occurring bacteria oxidise the ammonia, use it to grow, and convert it to nitrite (NO2-). This is an aerobic process that needs oxygen to occur. The bacteria that convert ammonia to nitrite are known collectively by their genus name Nitrosomonas. Like ammonia, the nitrite produced by the Nitrosomonas bacteria is toxic to aquatic organisms and must be oxidised further to a less toxic form of nitrogen. This is accomplished by another naturally occurring genus of bacteria referred to as Nitrobacter. These bacteria metabolize and oxidise the nitrite (NO2-) produced by Nitrosomonas and convert it to nitrate (NO3). Oxygen is also consumed in the creation of nitrate. Nitrate is the end product of the conversion of ammonia and nitrite and is non-toxic at the levels usually found in an RAS (>200 mg/L). Further information can be found in SRAC Publication No. 451, Recirculating Aquaculture Tank Production Systems: An Overview of Critical Considerations. The reaction sequence accomplished by the nitrifying bacteria can be simplified as follows:

What does starting a biofilter involve?

Starting a biofilter involves managing and controlling the seeding of nitrifying bacteria cells in a biological filter.

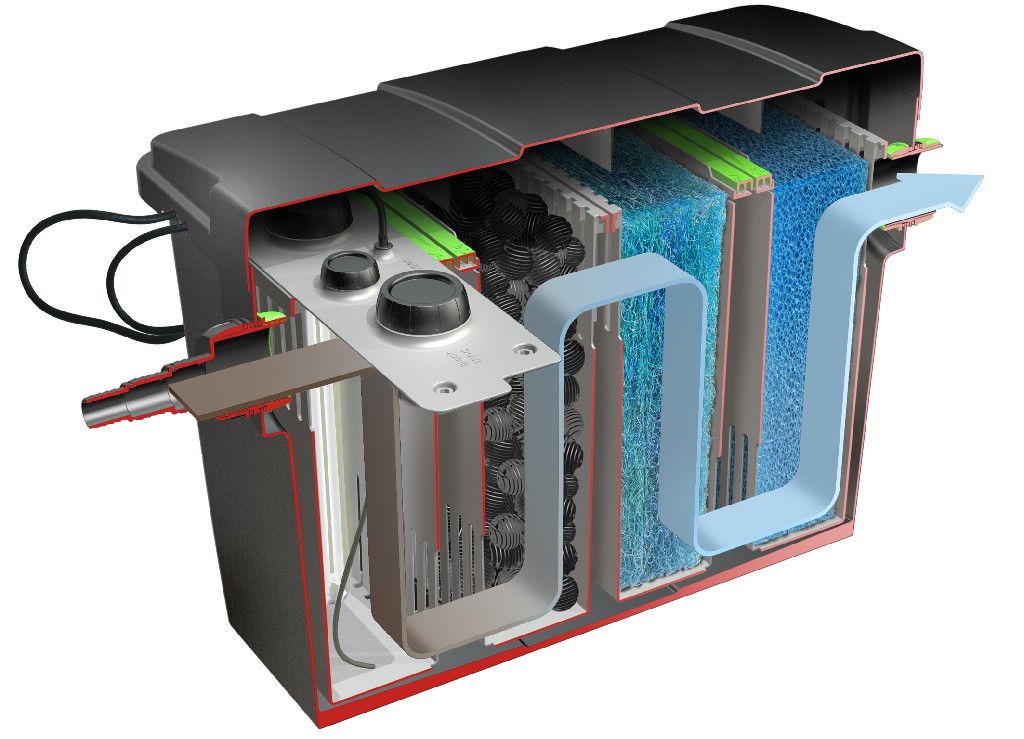

A biological filter consists of non-corroding material such as plastic, fiberglass, ceramic or rock that has large amounts of surface area nitrifying bacteria cells can colonise.

To make biofilters more compact, material that has a large surface area per unit volume is usually chosen. This unit of measure is usually referred to as the specific surface area (SSA) of the biofilter media. Nitrifying bacteria cells grow on all surfaces of the biological filter media and, in fact, on all wet surfaces of the system, such as the insides of pipes, tank walls, etc. Bacteria follow a continual cycle of growing and multiplying, maturing and dying, sloughing off of the media, and being replaced by new cells. A biofilter is started by adding bacteria to the system, which can be done in several ways. Nitrifying bacteria can be introduced with:

- Water or bits of biofilter media from an already operating system.

- With pond sediment or barnyard soil.

- With small numbers of “starter” animals. These animals will have to survive the rigours of elevated ammonia and nitrite concentrations while bacteria cells reproduce and colonise the biofilter media.

Whatever method is used to add bacteria to a system, there is a danger of introducing pathogens as well. The choice of a method should be evaluated as part of the overall facility management and biosecurity plan.

One strategy for starting a biofilter, sometimes called the cold start method, involves stocking the cultured species without having an activated biofilter. Operators must be prepared to deal with the resulting rapid increase in ammonia and nitrite concentrations and to reduce them to tolerable levels through water exchanges. Feed rates must be reduced or feeding must be suspended until biofilter activation occurs.

The cold start method has the advantage of using the bacteria that entered the system with the first animals introduced, bacteria that must have been well-suited to the conditions from which those animals came.

This passive biofilter activation, however, can be a slow and stressful process for the animals and the system operator. A more desirable method is to develop the nitrifying bacteria within the biofilter before stocking the species to be cultured. The advantages of “seeding” nitrifying bacteria are: 1) reducing stress on the newly introduced stock 2) shortening the growing cycle with higher feed rates from the first day of stocking (which is important to the economics of an RAS) 3) creating better water quality, which improves health, growth rates, and survival.

Steps in starting biofilters

To start biofilters you must have a source of nitrifying bacteria and create conditions that will encourage their growth. The following procedure assumes that animals are not yet in the system. Adding nutrients to support the growth of bacterial cells can create concentrations of ammonia and nitrite that can be lethal to your cultured species.

- Prepare the water chemistry of the system before introducing either nitrifying bacteria or animal stock. The system should be operating and passing water through the biofilter. If the culture tank is not yet ready for use, it is possible to recirculate water only through the biofilter unit. System water should be free of residual chlorine that may have been used for disinfection or pathogen control. System water should be warmed or cooled to near the temperature at which the system will be operated when stocked; pH, salinity, alkalinity and hardness should match the requirements of the incoming stock.

- Provide alkalinity, a carbon source. Carbon dioxide dissolved in the system water is a source of carbon for the developing bacteria cells, but carbonate (CO3-2) and bicarbonate (HCO3-) ions are also carbon sources and are more easily added and controlled. Add sodium bicarbonate (NaHCO3), or common baking soda, to increase alkalinity. Baking soda is inexpensive and safe to use. Increase system alkalinity to about 150 mg/L initially. Alkalinity at this level will support the growth of Nitrosomonas bacteria, but the authors have had better success in establishing Nitrobacter bacteria at a higher alkalinity of about 200 to 250 mg/L. When Nitrobacter does become established, alkalinity can be allowed to decline to operational levels.

As a rule, to raise the alkalinity by 10 mg/L, add 53 grams of sodium bicarbonate for every 3,785 litres (0.117 pounds or 1.86 ounces per 1,000 gallons) of system water capacity.

- Adjust pH if necessary. With alkalinity at the level suggested above, pH is usually not a problem. A range of 6.8 to 7.2 is best. The lower healthy limit of pH for nitrifying bacteria, about 6.8, is usually not reached unless a high concentration of carbon dioxide is present. During the start-up of a new system, this is unlikely unless the source water is high in carbon dioxide. Circulation and aeration or degassing of the water in the system will reduce CO2 concentration.Water Quality data for biofilter start-up. (DeLong, unpublished data, North Carolina Fish Barn, July 1998)

Using bacterial preparations in the biofilters

A number of prepared mixes of cultured nitrifying bacteria are available from suppliers, for both freshwater and marine applications. These are available as dry powders or concentrated liquid suspensions. They may arrive as a chilled culture along with the inorganic chemicals needed for their initial nutrition as they become established. Although they are not essential, these bacterial preparations can shorten the time that it takes to establish the biofilter.

Tips and tricks

- Temperature can be raised slightly to increase the rate of reaction of biological and biochemical processes, thus speeding the development of a nitrifying bacteria population. Increase the temperature no more than 2 to 3 °C (3.6 to 5.4 °F) above the anticipated culture temperature to avoid a major die-off of bacteria when the temperature is reduced to operational levels.

- The total volume of a system can be reduced by operating the culture tanks with a lower water level during the start-up of the biofilter. With a smaller volume of water, temperature can be changed more quickly and the quantity of nutrients required for dosing the biofilter will be reduced, which makes the process more cost-effective.

- It can be difficult to start a biofilter containing brand new media, possibly because the media may still have a slick, shiny surface to which it is more difficult for bacteria cells to attach. Once the first growth of bacteria is established, however, subsequent cycles usually start more quickly.

- With moving bed or mixed bed biofilters, bacteria may be slow to colonise because of excessive agitation or aeration of the media bed. This is essentially a mechanical problem caused by the abrasion of the surface of the biofilter elements, continually scraping off bacteria cells that are trying to adhere. Reducing the physical agitation of the media bed by reducing aeration and/or water flow through the bed can help.

As more bacteria cells become established on the media surfaces, as evidenced by daily decreases in ammonia and nitrite concentration, aeration and agitation can be gradually increased.

Adopt the method that works best for your operation and your systems. If you are learning to start and operate systems, keep records and notes of your experiences so that you can determine what works or doesn’t work for your situation.

Go Back to Aquaponics System